At present, pulp molding has been well applied and promoted in China, and is known as a product mold for the environmental protection industry. The vacuum molding molds used in the past were gypsum molds or electroplated copper molds, so the cost was very low and the price was also low.

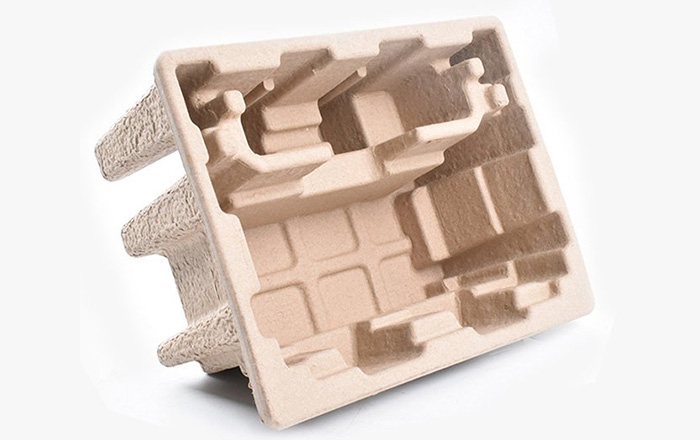

The new type of pulp molded product paper tray packaging is a new type of environmentally friendly packaging, also known as pulp molded packaging, which is processed from raw materials such as sugarcane pulp and bamboo pulp. The molds used in the production process of paper tray packaging include forming molds, punching molds, hot pressing molds, and knife molds. The material of pulp molding is mostly aviation aluminum, and there are also steel molds and copper molds, which are more expensive.

Pulp molding is composed of several sets of molds with higher material requirements than vacuum molding, which is one of the reasons why pulp molding is more expensive than vacuum molding.

The price of pulp molding varies depending on the customer's requirements, precision and equipment countertop, as well as the precision of the processing technology. Often, high-quality molds not only focus on product performance, but also on product aesthetics and visual effects.