Available materials and colors to choose from:

Material: Environmentally friendly raw materials such as sugarcane pulp (core), wood pulp, bamboo pulp, waste pulp, etc

Color: Special colors such as white paste, A4 paper white, black, gray, yellow, red, green, etc

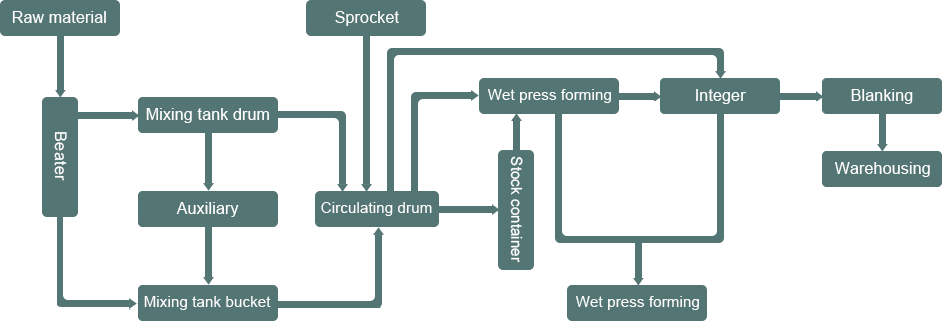

1. The production process is a closed cycle production process with no emissions and no pollution to achieve clean production. The process flow chart is as follows:

2. Green and environmentally friendly: Made of 100% plant fiber raw materials, 100% biodegradable, 100% recyclable, it is an environmentally friendly packaging product that replaces plastic packaging. Complies with environmental packaging requirements in countries such as the European Union, the United States, and Japan.

3. Product features: It has good waterproof, moisture-proof, shockproof, anti-static, oil proof and other properties, meets food grade packaging standards, and can be stacked to reduce storage and transportation costs.

4. Strong plasticity: Design the structural shape of paper tray packaging based on the shape of the applied product, which can be used as inner lining packaging or outer packaging box.

5. Raw materials used: sugarcane pulp, bamboo pulp, raw wood pulp, cowhide pulp, corrugated pulp (also known as waste pulp), white paper edge pulp, newspaper pulp, etc. can be used. Raw materials can be selected based on product positioning and cost budget.

6. Product color: Wet press paper tray is mainly white and black, dry press paper tray is mainly yellow, and can be customized in any color according to needs.

7. Production process: There are wet pressing process, semi wet pressing process, and dry pressing process, which can be selected based on product positioning and packaging cost budget.

8. Application scope: Widely used for packaging in various industries such as electronics, digital, electrical, cosmetics, alcohol, gifts, containers, toys, pharmaceuticals, food, etc

9. The company mainly engages in pulp molding (environmentally friendly paper tray dry pressing, wet pressing high-quality packaging products), with unique mold research and production capabilities. The system provides customers with innovative and unique packaging solutions such as packaging planning, packaging design, and production sampling.

The company's business scope includes environmentally friendly pulp molded packaging products such as consumer electronics, gift packaging, cosmetics packaging, toy packaging, tea, tobacco, alcohol packaging, logistics and transportation packaging, etc. The company adheres to the principle of quality first and integrity first

To provide customers with thoughtful services and high-quality green and environmentally friendly products, and to make the contribution that our company should have in the global environmental packaging industry!

10. The factory covers an area of 10000 square meters and has two white system production lines